FMW Non Wood Dewiring – Automatic Dewiring (Extractor)

Maximize Efficiency and Safety in Your Operations with FMW’s Automatic Non Wood Fiber Bale Dewiring

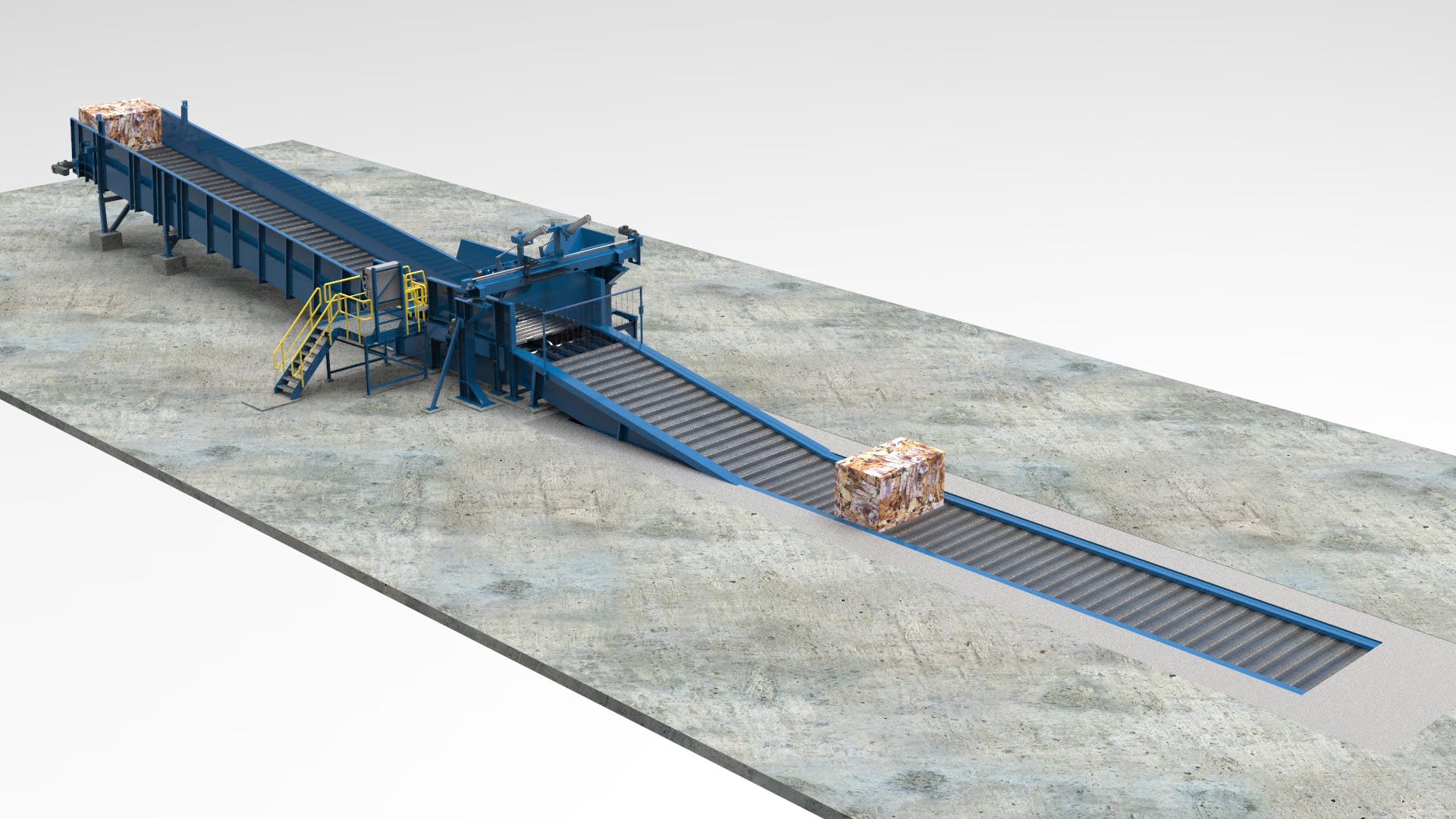

Facilities often face challenges with manual bale dewiring, a labor-intensive, time-consuming process that poses safety risks for workers. The need for a more efficient and safer solution is vital for operations when working with bagasse . Introducing FMW’s Automatic Non Wood Fiber Bale Dewiring Extractor which is designed to automate the dewiring process, reduce labor costs, and improve safety standards in your facility.

Introducing the Automatic Bale Dewiring Extractor

The Automatic Bale Dewiring Extractor is a machine that streamlines the dewiring process. It efficiently and safely removes contintously wires from all commercial bales, ensuring optimal processing and recycling of materials without interference from binding materials.

The FMWs Extractor is a reliable solution that improves efficiency and safety in your facility.

Key Features of the FMW Extractor

The Automatic Bale Dewiring Extractor is designed to streamline the dewiring process with its unique set of features:

- Two-Step Dewiring: The Extractor operates in two steps, cutting wires on the bottom of bales and removing them from the top.

- Safety Features: The Extractor includes safety features like a micro-wave barrier to detect the presence of bales in the processing area, ensuring safe dewiring.

- Top Wire Removal: The second step involves removing the cut wires from the top of the bales, captured by the fingers of the winding shaft and wound through the rotation of the shaft.

- Adjustability: The height and lateral position of the winding unit can be adjusted to accommodate various bale sizes.

- Continuous Operation: The machine can work continuously without the need for stopping the conveyor.

How it works:

The bagasse bales are fed to the Receiving Conveyor by a clamp truck and advanced to the Dewiring section. The wires are cut from the bottom and continuously extracted from the top. Removed wires are cut periodicly discharged either into a container, a wire coiler or a wire shredder. Dewired recycled paper bales are conveyed directly either into a bale breaker or onto a conveyor.

Why Choose the FMW Automatic Bale Dewiring Solution?

Implementing the Extractor in your facility will lead to immediate improvements in efficiency and safety, providing a competitive edge in the industry. This technology, combined with FMW’s expertise, ensures a reliable and cost-effective solution for your recycling operations.

It is ideal for various applications in the industry, such as pulp and paper facilities, material recovery facilities (MRFs), waste-to-energy plants, and fiber recycling operations.

Conclusion

The Extractor offers a comprehensive solution to the challenges faced by recycling facilities in manual bale dewiring. With its advanced features, focus on safety, and adaptability to different applications, it is the ideal equipment to enhance efficiency and safety in your operations.

To learn more about the FMWs Extractor and how it can benefit your operation, contact our team of experts today.

Discover more about FMWs Non Wood Fiber Handling Solutions.

Our non-wood fiber preparation solutions range from dewiring and storage to processing, each designed to enhance the quality and suitability of fibrous materials for various downstream processes. Whether it’s the initial removal of contaminants like wire and plastic from feedstock with our dewiring solutions, or the handling and storage of materials with our storage solutions, FMW has the expertise to ensure efficient material handling.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.