FMW Pulp Bale Handling Solutions

How to Optimize your Pulp Bale Handling for Maximum Efficiency

The pulp and paper industry is constantly evolving, with new technologies and innovations driving growth and efficiency. In this industry environment, the efficiency and precision of handling pulp bales is paramount. At FMW Industries, we understand the unique challenges this industry faces and have developed different solutions to streamline your operations.

Precision is key

Pulp bale handling is an essential process in the paper industry, as it ensures the efficient and safe transportation of raw materials from delivery to the pulping process. Key demands in the industry include safety, speed, and reliability. We understand these needs and have developed a suite of solutions that cater to your specific requirements.

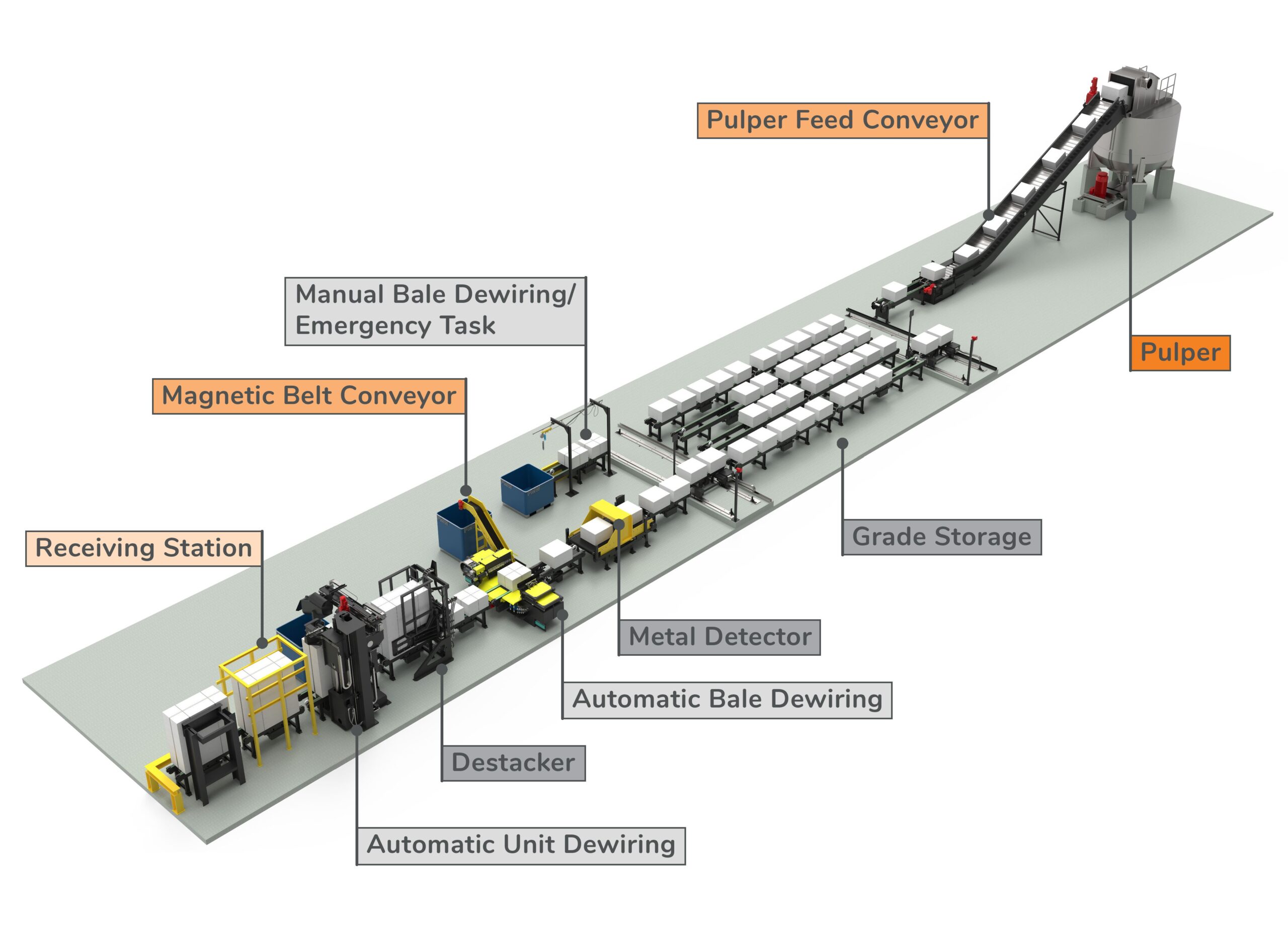

Let’s dive into the process using an example: Imagine a Pulper Feeding System, where precision is key. Our comprehensive solution includes all process stages to the pulper.

Explore our solutions

Here you will find an exemplary overview of the process steps as well as our solutions. We would also be happy to find the right solution together with you.

Dewiring Solution

Pulp Bale Handling

Learn more about:

- Unit Destacking

- Bale Turning

- Bale Stacker

- Metal Detector

From Receiving to the Pulper

The efficient handling of pulp bales stands is a cornerstone of successful production. We understand the industry places a premium on safety, speed, and reliability; our suite of pulp bale handling solutions is carefully designed to meet these crucial requirements.

FMWs Dewiring Solutions from Units to Bales

FMWs fully Automatic Dewiring Solutions are our commitment to safety and efficiency. They are pricisely and securely removing wires from units (Automatic Unit Dewiring) or pulp bales (Automatic Pulp Bale Dewiring), drastically reducing the risk of accidents and optimizing the overall operational efficiency. By automating this critical step, we ensure your operations run smoothly, without interruptions.

Recognizing that some operations prefer a balanced approach between automation and hands-on control, the FMWs Semi-Automatic Unit Dewiring system offers the best of both worlds. It maintains the advantages of improved efficiency and safety while allowing for a level of operator interaction.

Redefining the entire workflow

At FMW Industries we’re here to improve your workflow. Our comprehensive product range extends beyond dewiring solutions to optimize your entire process, including efficient bale handling. We understand that every step in the process is critical, which is why we offer solutions that cover dewiring and the handling of bales with precision.

Our FMWs Unit Destacker, for instance, is engineered to minimize handling requirements while efficiently destacking units, ultimately optimizing your material flow and reducing downtime. If you’re in need of optimized storage space, our FMWs Bale Stacker is an ideal solution. It maximizes available resources and caters to your facility’s layout, streamlining the storage process, enhancing material management, and contributing to a more efficient operation.

For industries with high hygienic standards, our Bale Turner is the perfect machine. It efficiently reorients and prepares bales, ensuring hygienic compliance and quality assurance. Last but not least, our integrated Metal Detector plays a crucial role in quality control by guaranteeing that only pure pulp enters your production line. This safeguard protects your operation from costly damage and downtime by identifying and removing contaminants, thus enhancing the overall quality of your final product.

Take the next step

We redefined the pulp bale handling process. Our solutions offer a combination of safety, efficiency, and productivity, meeting the industry’s most critical demands. Whether it’s unloading, dewiring, destacking, metal detection, emergency response, storage, or pulper feeding, we have you covered.

Contact our sales team today to discuss how our solutions can transform your operations.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.