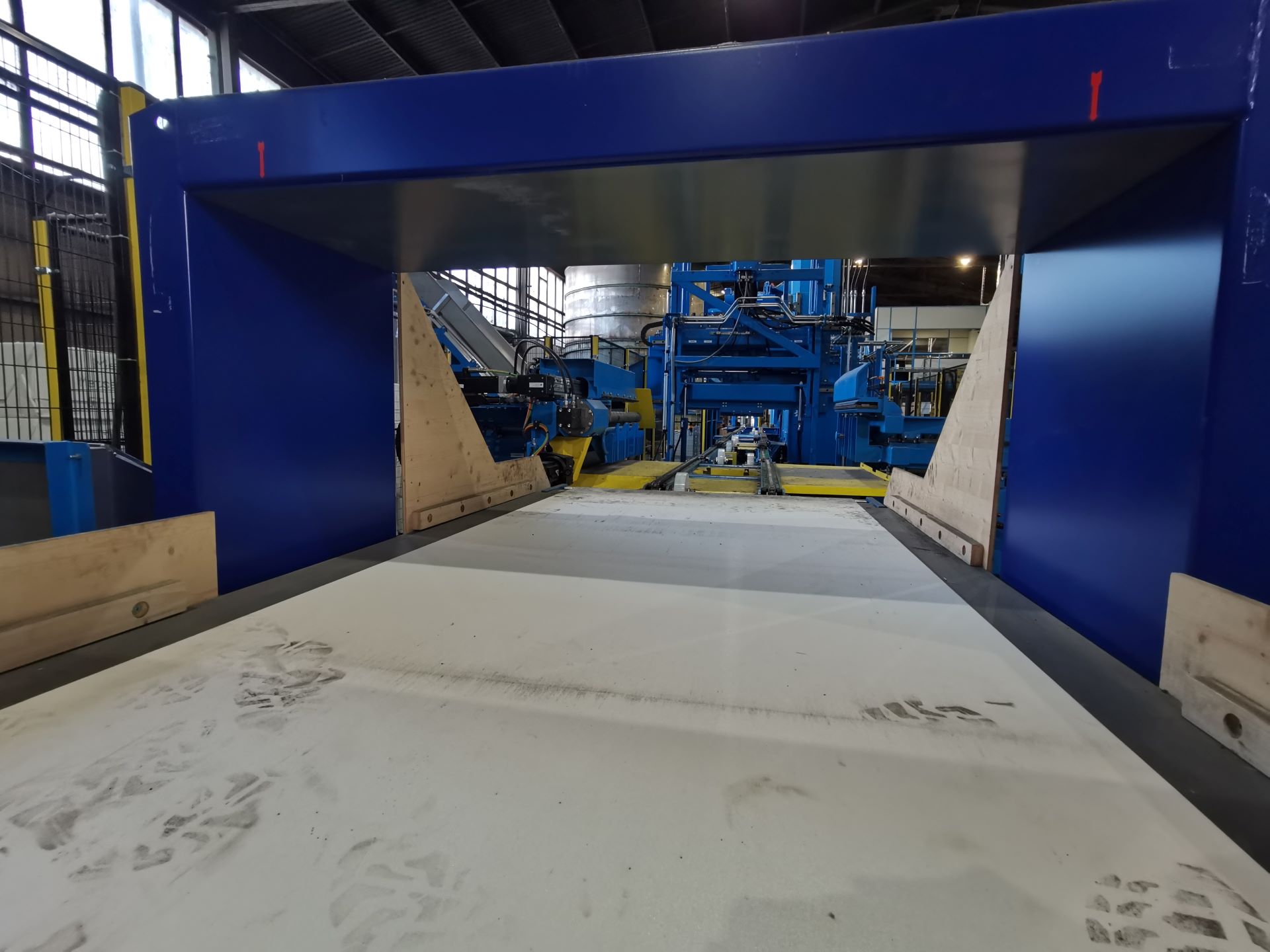

FMW Handling Solution – Metal Detector

Protect Your Pulping Process and Equipment with FMW’s Metal Detector

In the pulp and paper industry, metal contaminants in pulp feed can cause severe damage to pulping equipment and compromise the quality of the final paper product. These issues can lead to equipment damage, production downtime, increased maintenance costs, and potential safety hazards for personnel. To address this challenge, FMW offers a metal detector designed to detect metallic contaminants from pulp feed, ensuring the purity of the material entering the pulping process.

Key features of the Metal Detector

- Metal contaminant detection

- Product quality assurance

- Equipment protection

- Process efficiency

- Cost savings

How it works:

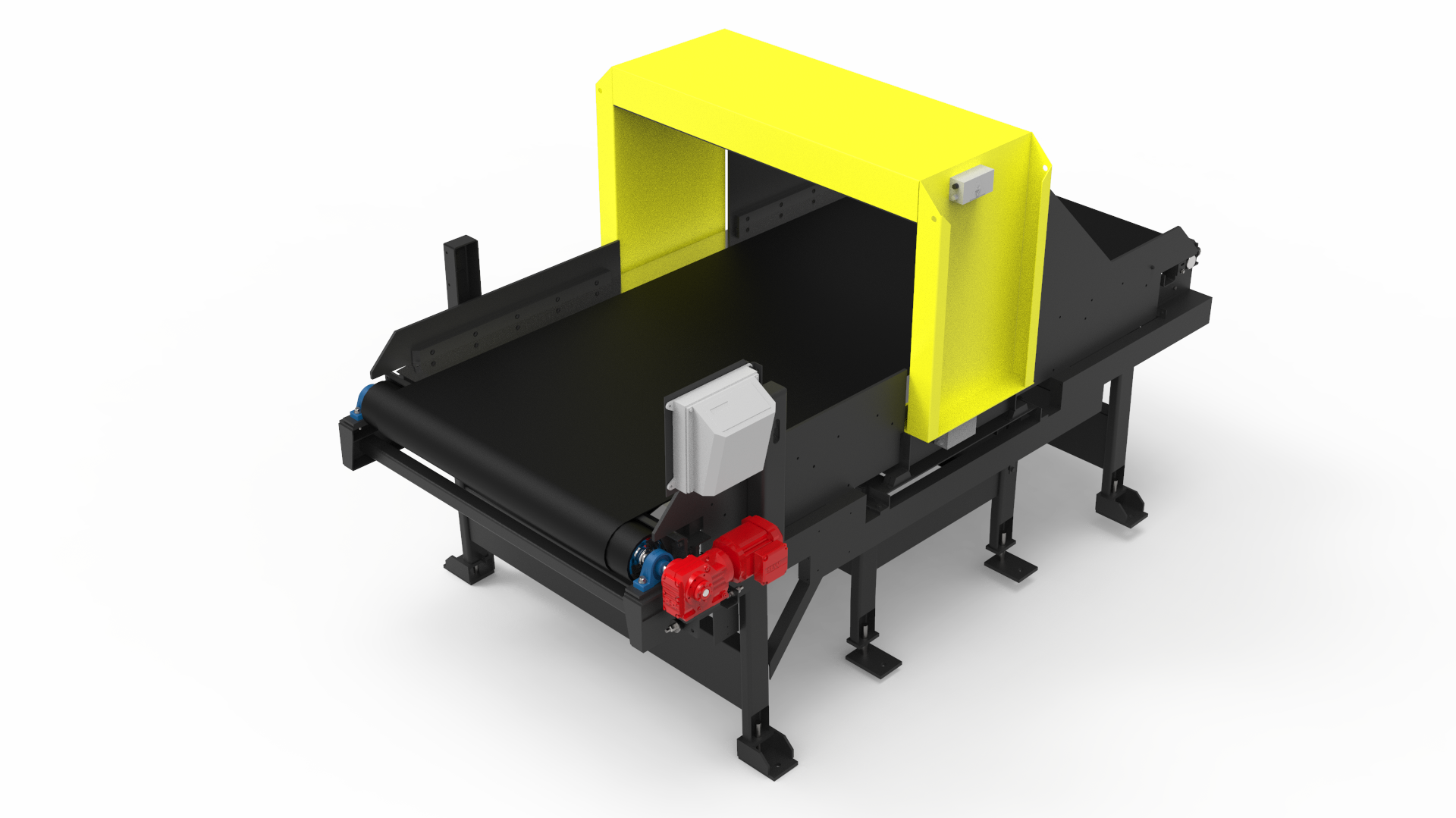

The metal detector machine typically consists of a conveyor system that transports the pulp material through a sensor or detector unit. When metallic contaminants are detected, the machine triggers an alarm or automatically activates a rejection system to remove the contaminated bale from the feed stream.

Why and When to Choose FMW’s Metal Detector

Implementing FMW’s metal detector in your bale handling process can protect your equipment, optimize process efficiency, and ensure the quality of your final paper products. By implementing this detector into your process, you can prevent costly production stoppages, equipment repairs, and product waste, ultimately leading to cost savings and improved efficiency.

Conclusion

FMW’s metal detector is an essential addition to any pulp and paper facility, offering a range of benefits that protect your equipment, optimize process efficiency, and ensure the quality of your final paper products. Contact FMW today to discuss how to optimize your pulp bale handling process.

Discover more about FMWs Pulp Bale Handling Solutions.

Learn more about our comprehensive range of solutions, from fully automatic pulp bale dewiring to efficient pulp handling systems, all engineered with a focus on safety, efficiency, and customization. Our solutions are designed to seamlessly integrate with your existing operations, ensuring maximum productivity and minimum downtime.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.