FMW Wood Chip Screening Solution – Disc Screen

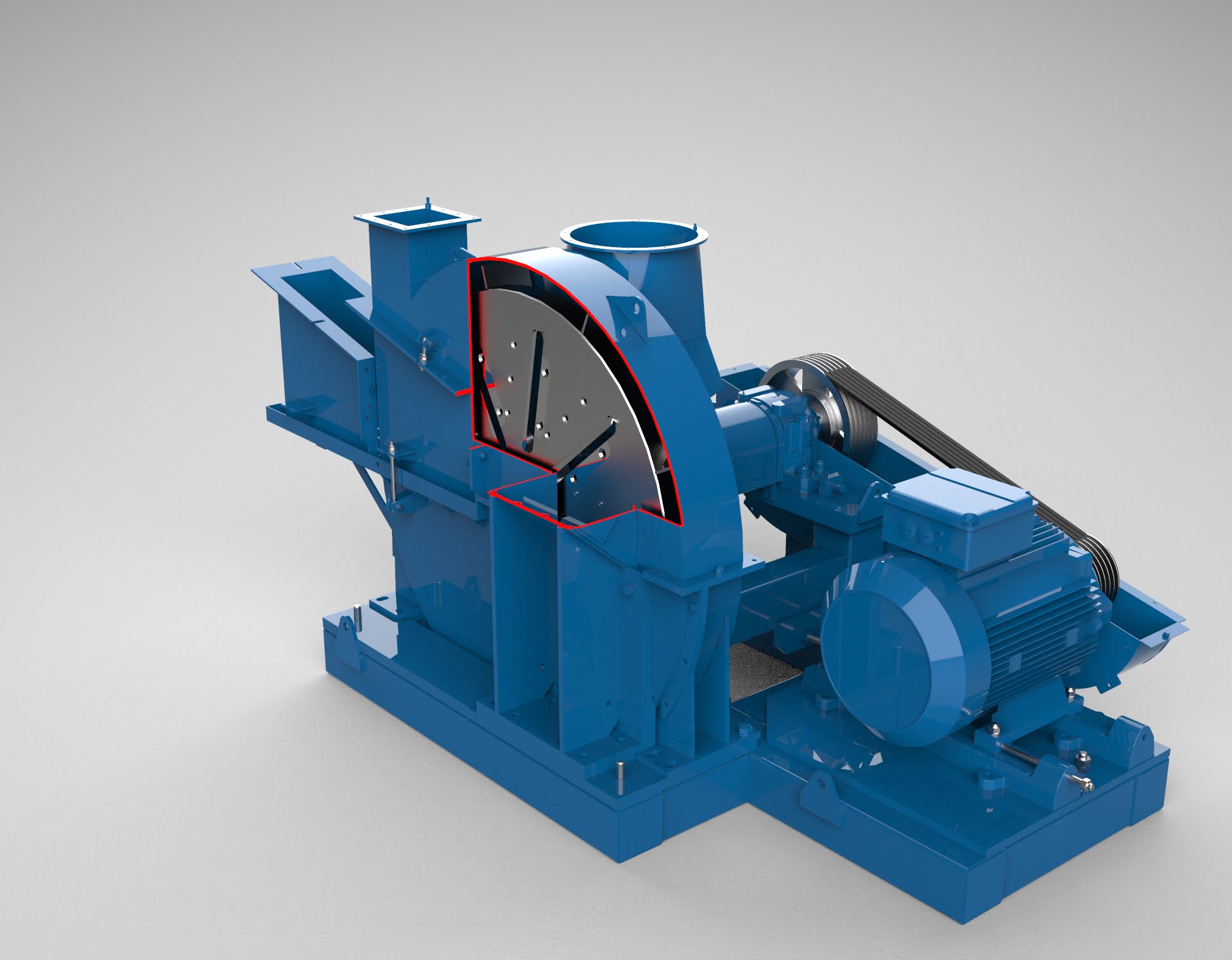

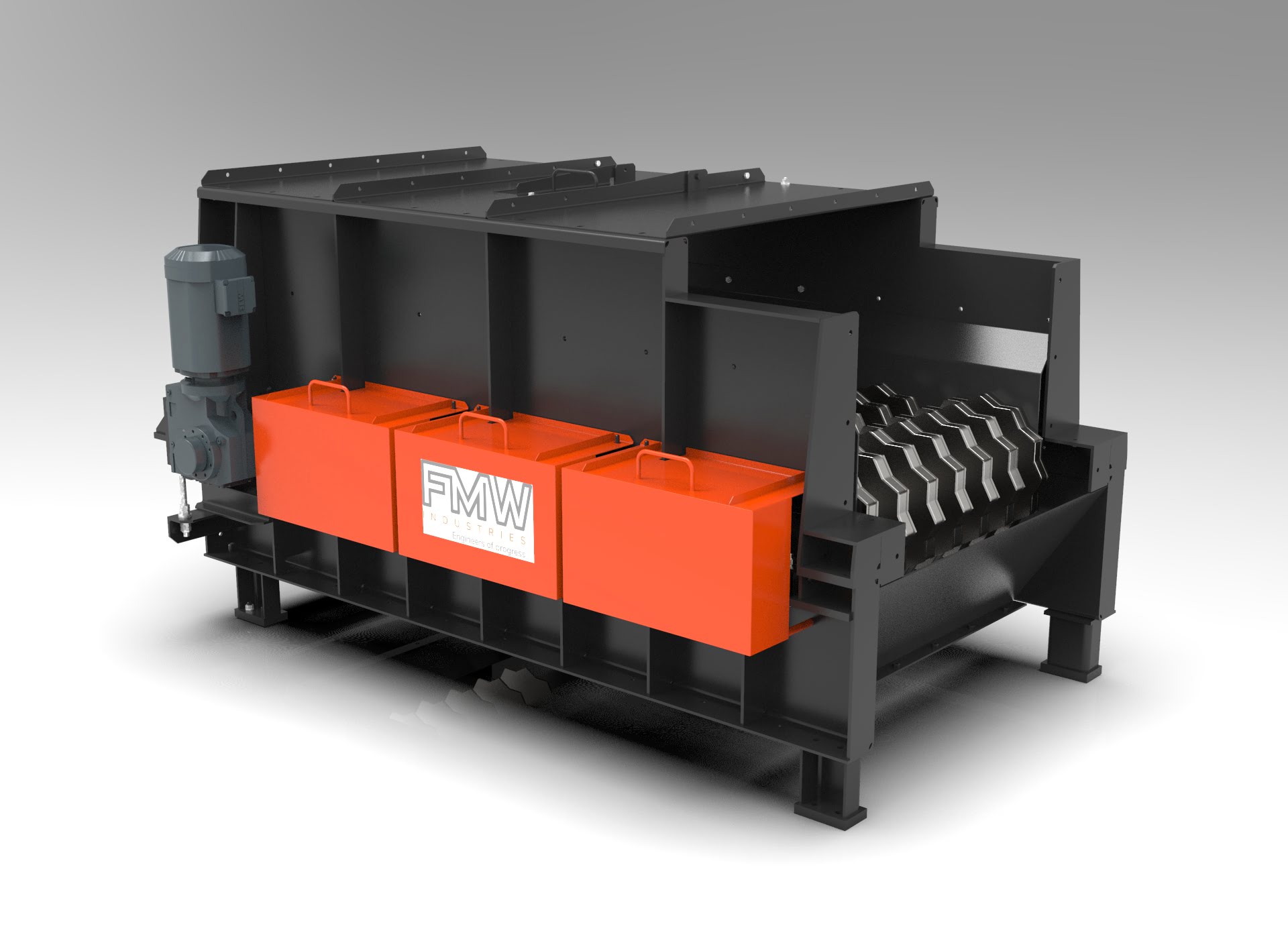

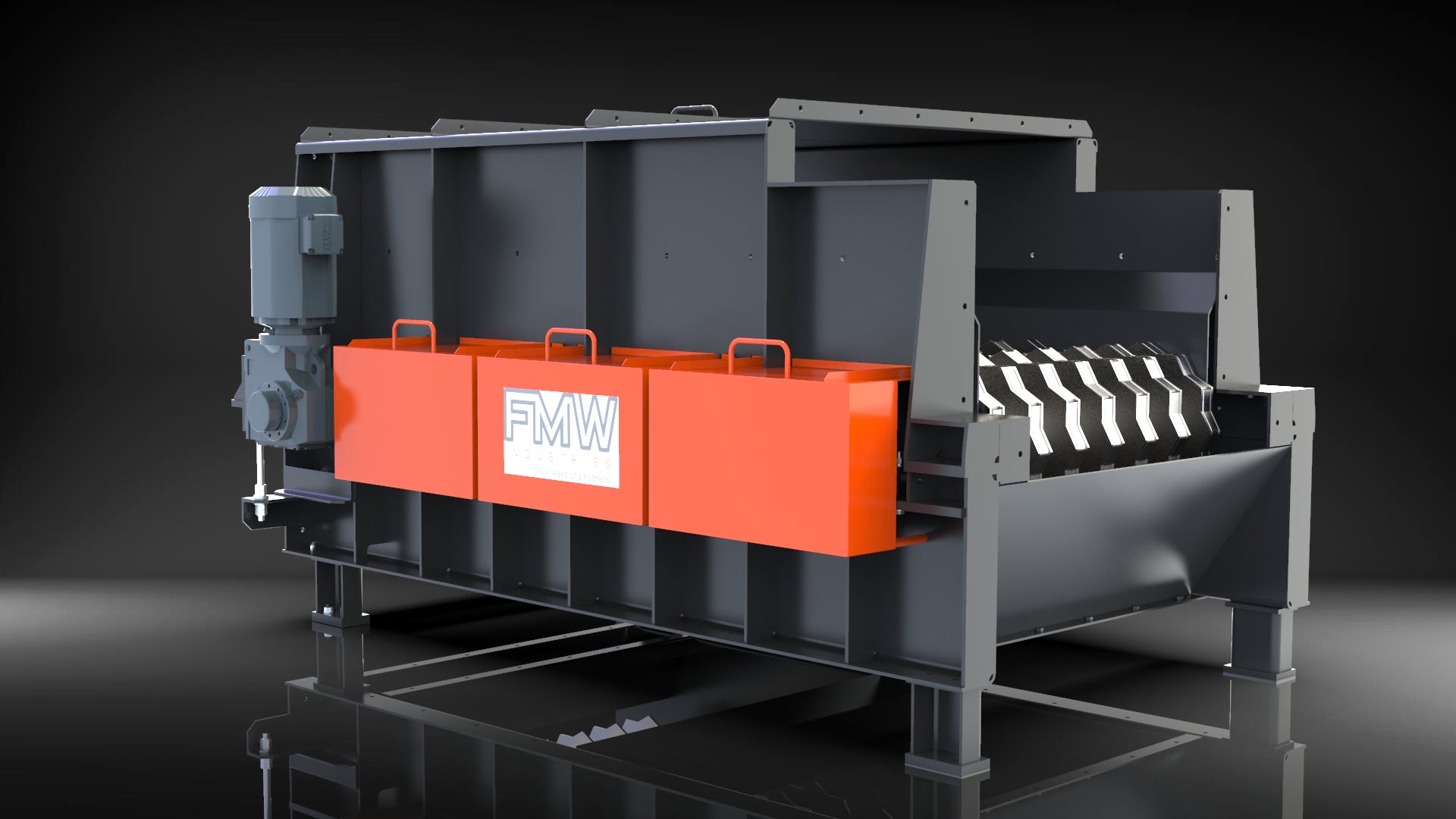

Introducing the FMW Disc Screen

In the highly competitive pulp and paper industry, efficient screening processes are crucial for maintaining productivity and reducing operating costs. Inefficient screening can lead to lower productivity, increased operating costs, and higher raw material usage. With the global pulp and paper machinery market size growing, it’s more important than ever to invest in reliable and effective screening solutions.

The FMW Disc Screen provides an efficient and comprehensive screening process for wood chips especially for quality control. It ensures high-quality acceptable material for downstream processes while efficiently managing large wood pieces.

FMW Disc Screen can handle high material flows, ensuring discharging of large wood particle sizes.

Keyfeatures:

The FMW Disc Screen is packed with features that make it the perfect choice for wood chip screening:

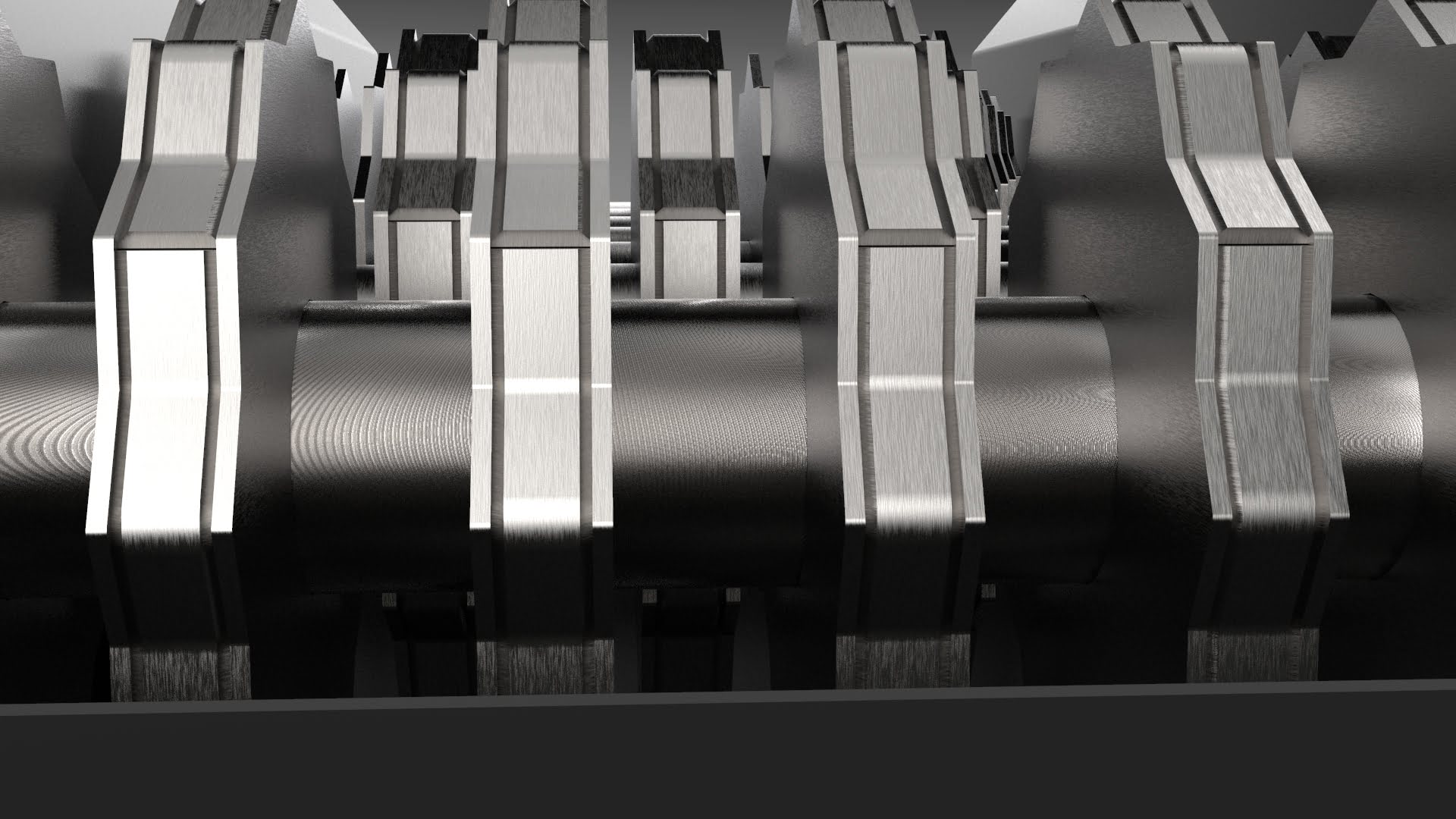

- Welded discs in wear-resistant steel

- Electriacal drive

- Optional: Screen cover: Equipped with a screen cover for added protection and safety.

How it works

The Disc Screen is used for pre-sorting and filtering out significant oversize particles.

The disc screen separates oversized material from the feed stream. The material hits the discs and falls through the gaps between the discs if it is not oversized. Oversized material remains on top of the discs and is discharged at the end of the Disc Screen into a box.

Main Advantages:

- The disc screen operates on a relatively simple and robust principle.

- It can handle high volumes of material efficiently

- High capacity throughput for maximum productivity

- Low operation and maintenance costs for cost-effective operation

- Space-saving installation for efficient use of facility space

Conclusion

To learn more about the FMW Disc Screen as an optional part of the FMW Screening-System and how it can benefit your operations, contact our experts today.

Discover more about the FMW Screening Solutions

The quality of the raw materials used directly impacts the final product quality. Wood chips, the primary raw material, need to be uniform in size and free from impurities to ensure a smooth and efficient production process. FMW Industries’ screening solutions provides a technology that effectively separates oversized chips and fines, leaving only high-quality material for further processing.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.