FMW Wood Chip Screening Solutions – Overview

Elevate Your Pulp and Paper Production with FMW Industries’ Wood Chip Screening Solutions

The pulp and paper industry is an essential player in the global economy, contributing to a wide range of applications, from packaging materials to printed media. In recent years, there has been a growing demand for higher quality and more efficient production processes. In response to this need, FMW Industries has developed a range of screening solutions designed to optimize chip quality and, consequently, improve overall production efficiency.

Why Chip Quality Matters in Pulp and Paper Production

The quality of the raw materials used directly impacts the final product quality. Wood chips, the primary raw material, need to be uniform in size and free from impurities to ensure a smooth and efficient production process. This is where FMW Industries’ Screening Solutions come into play, providing a technology that effectively separates oversized chips and fines, leaving only high-quality material for further processing.

FMW Industries’ Screening Solutions: An Overview

FMW Industries offers a comprehensive range of screening solutions tailored to the unique requirements of each production process. These solutions include:

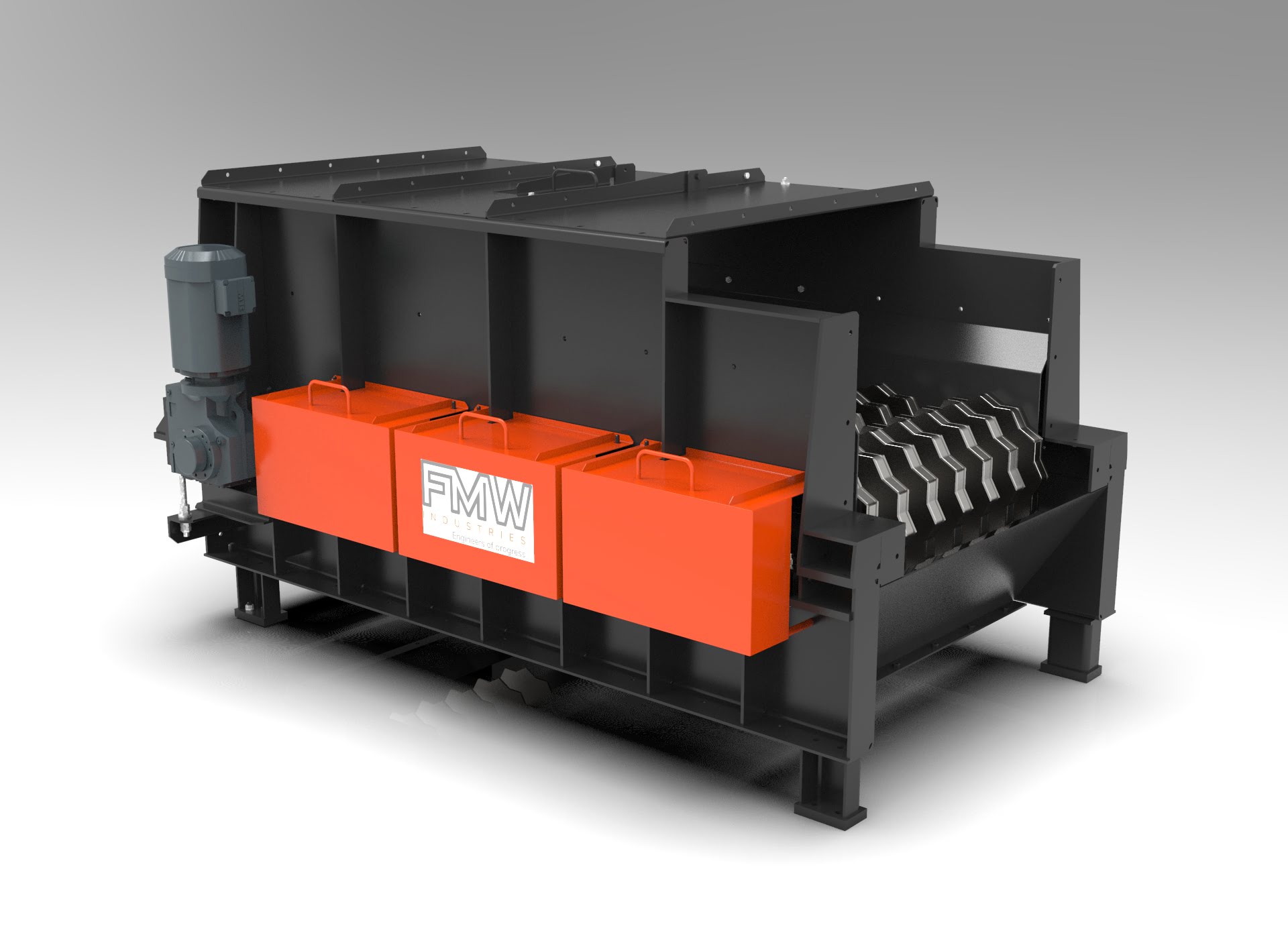

Disc Screen

The Disc Screen is a roller screen that further refines the quality of the material by separating overs and fines from the acceptable rate of chips. This advanced screening technology allows for a more precise separation of materials, resulting in higher yields and minimized losses in subsequent production stages.

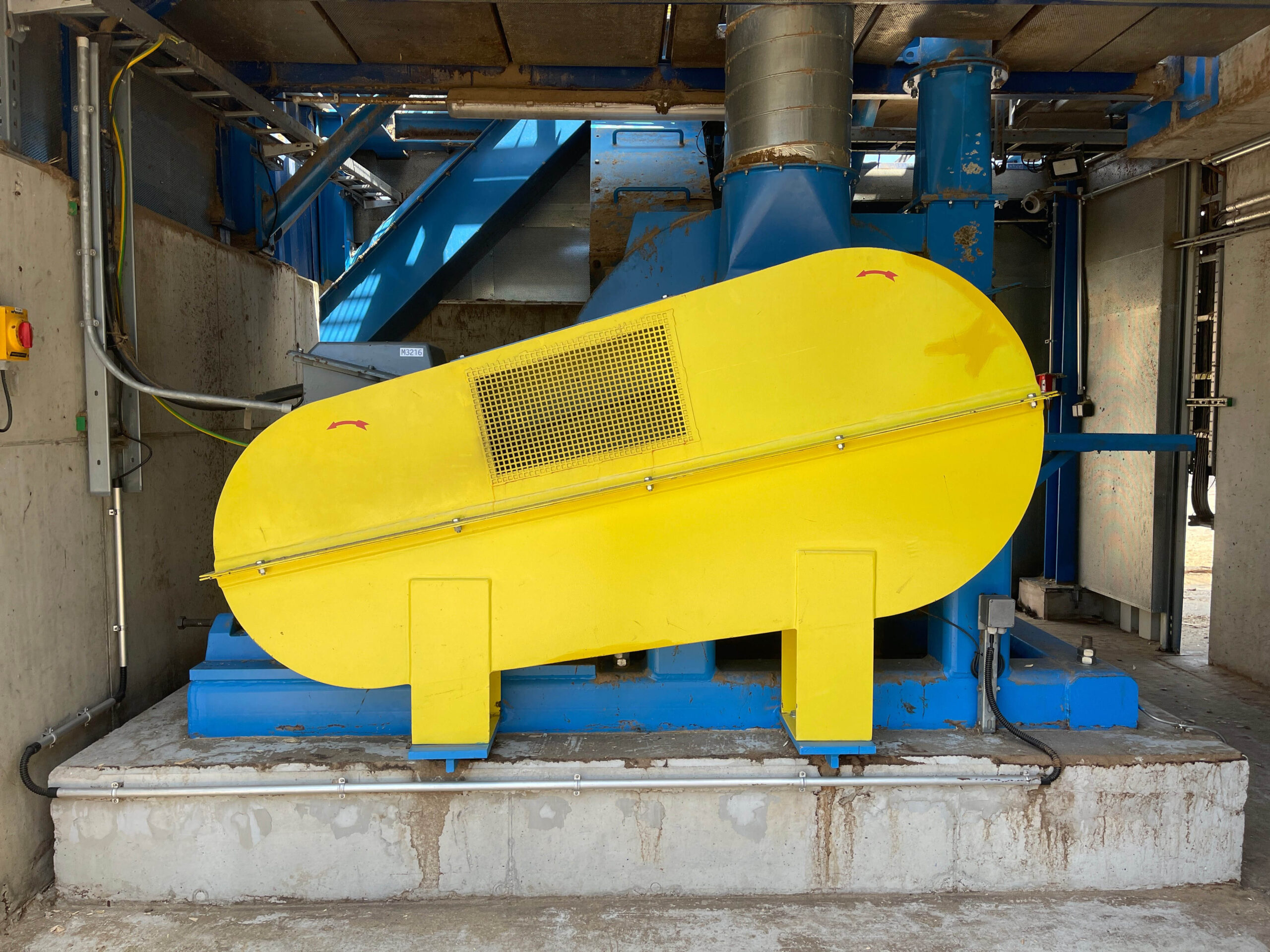

Chip Screen

FMW Industries’ chip screening systems are designed to efficiently separate acceptable material from oversized chips and fines. This meticulous process ensures that only high-quality material is retained, resulting in improved production efficiency and reduced operating costs.

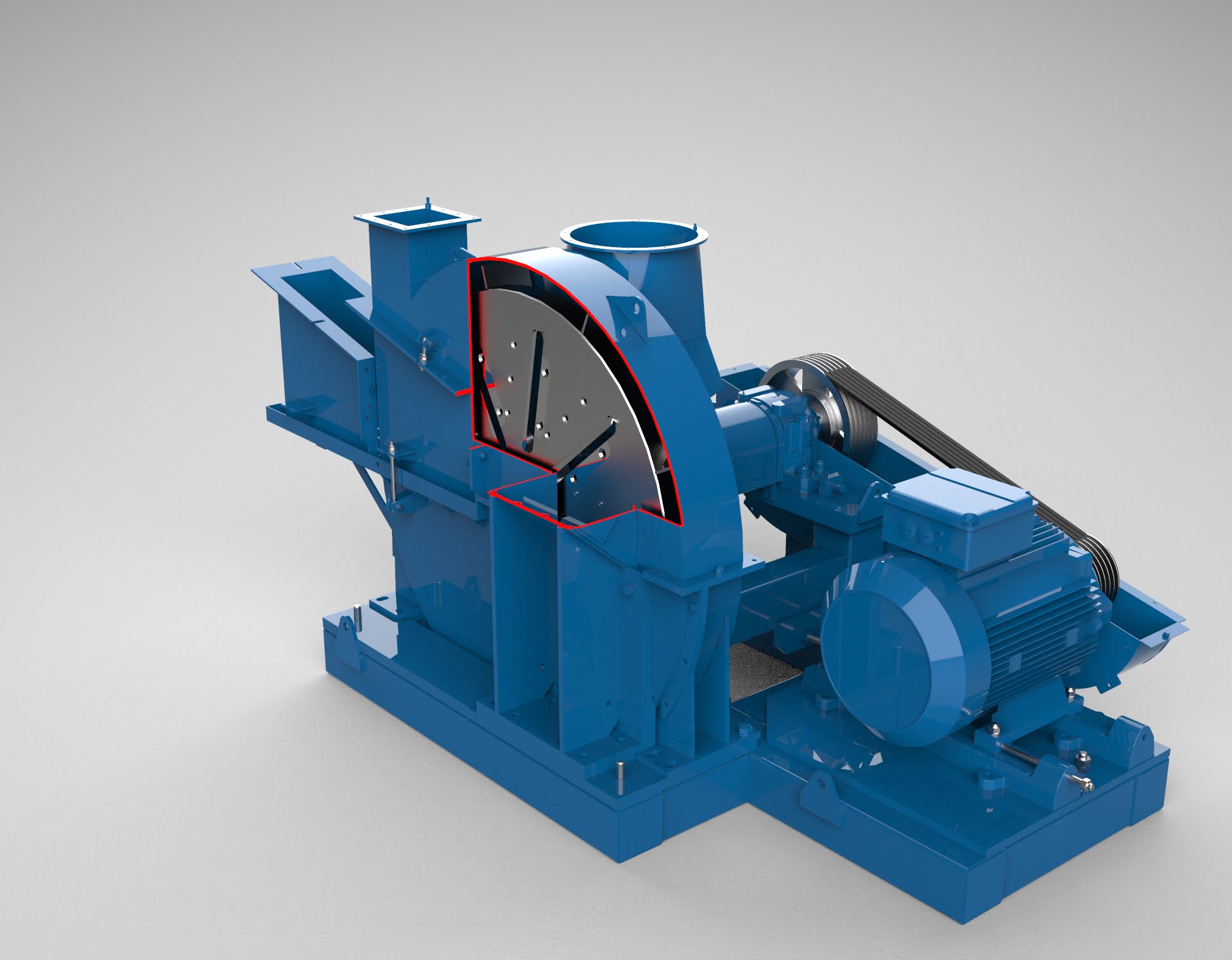

Re-Chipper

The Re-Chipper plays a crucial role in eliminating oversized chips for re-screening, by cutting them to the desired length. This process not only enhances the quality of the final product but also contributes to the overall efficiency of the production process.

The FMW Industries Advantage

We stand for our commitment to quality, experience, and professionalism. Our screening solutions are designed with the following key objectives in mind:

- Customized solutions for each unique production process

- FMWs quality for maximum wear resistance and longevity

- High-capacity throughput for increased productivity

- Low operation and maintenance costs

- Space-saving installation

By focusing on these objectives, FMW Industries ensures that our screening solutions provide maximum value to our customers, enhancing their production processes and boosting overall efficiency.

Conclusion

In the competitive landscape of the pulp and paper industry, optimizing the quality of raw materials is crucial to staying ahead. FMW Industries’ comprehensive range of screening solutions offers a reliable and efficient way to improve chip quality, resulting in higher yields and more efficient production processes. By partnering with FMW Industries, you can rest assured that you are investing in state-of-the-art technology that will elevate your production capabilities and drive your business towards greater success.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.