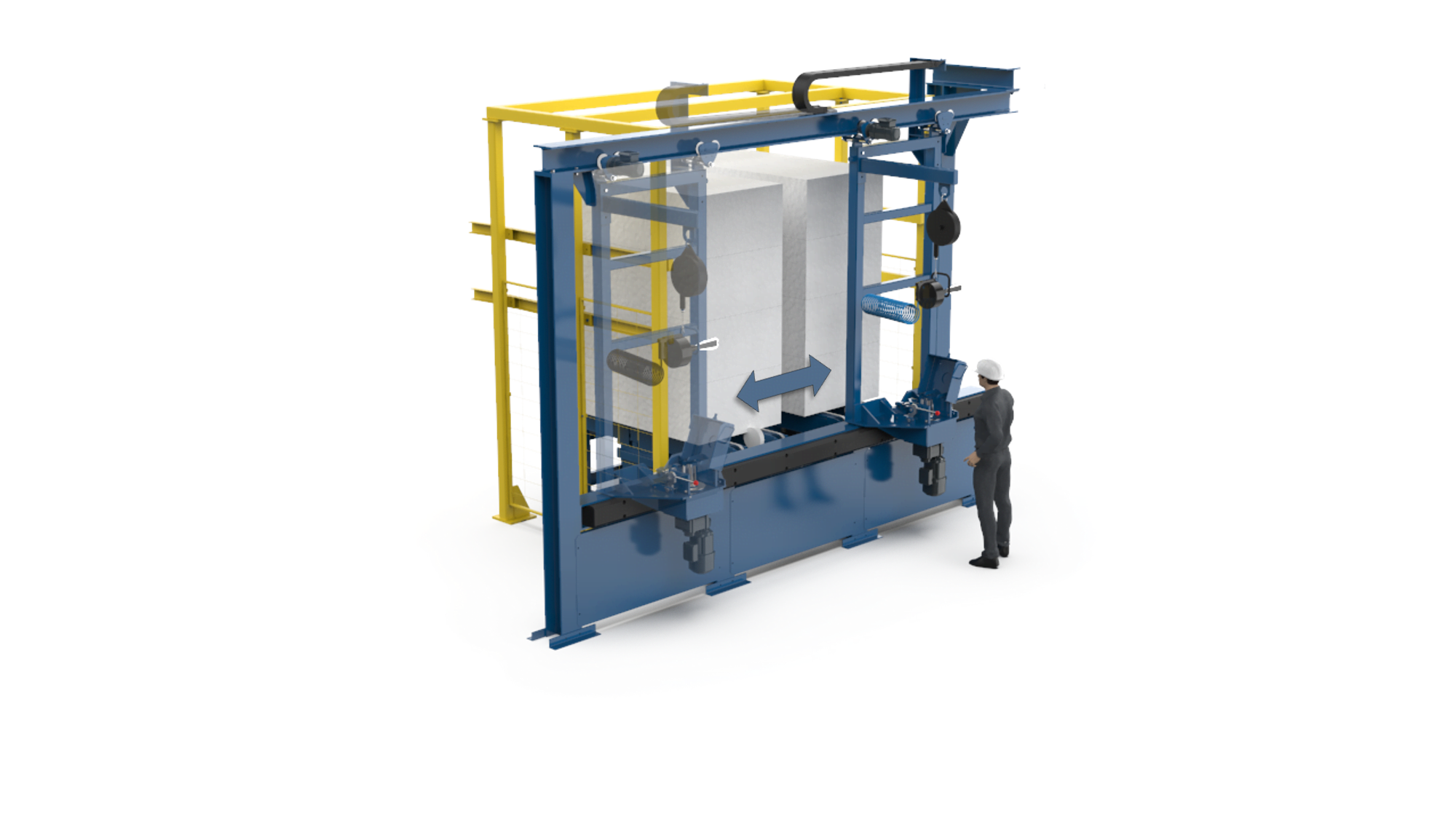

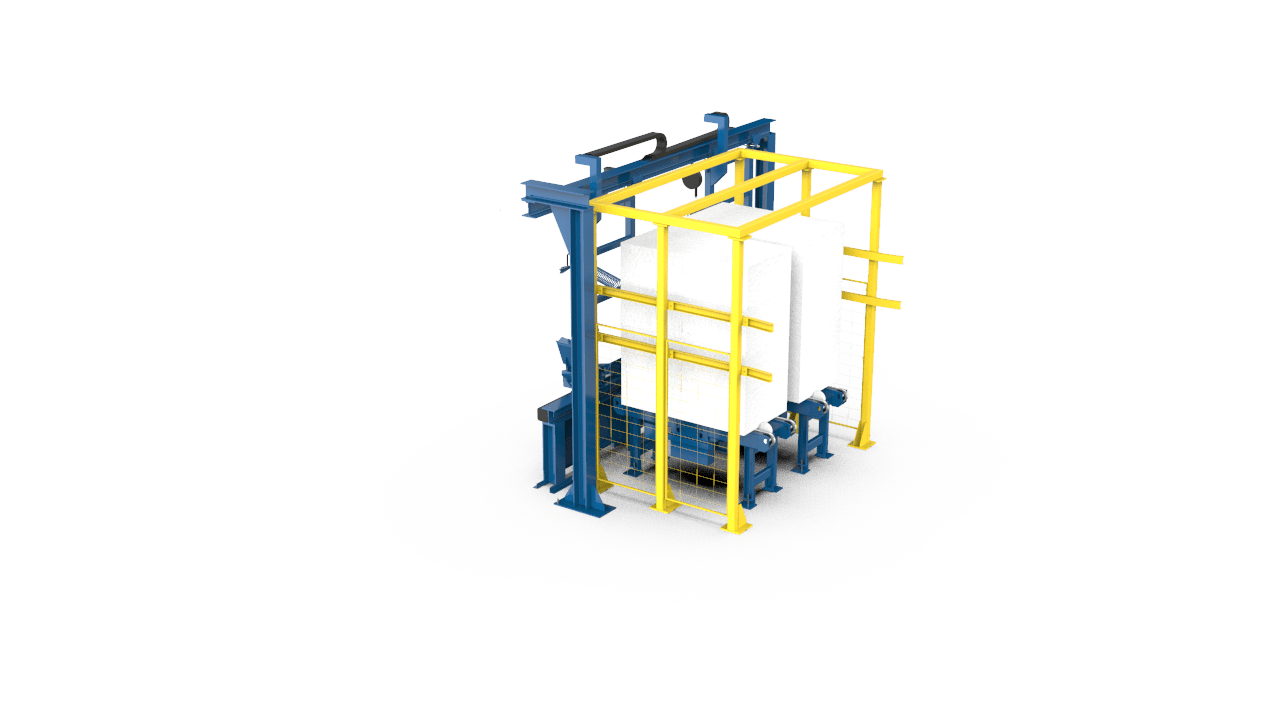

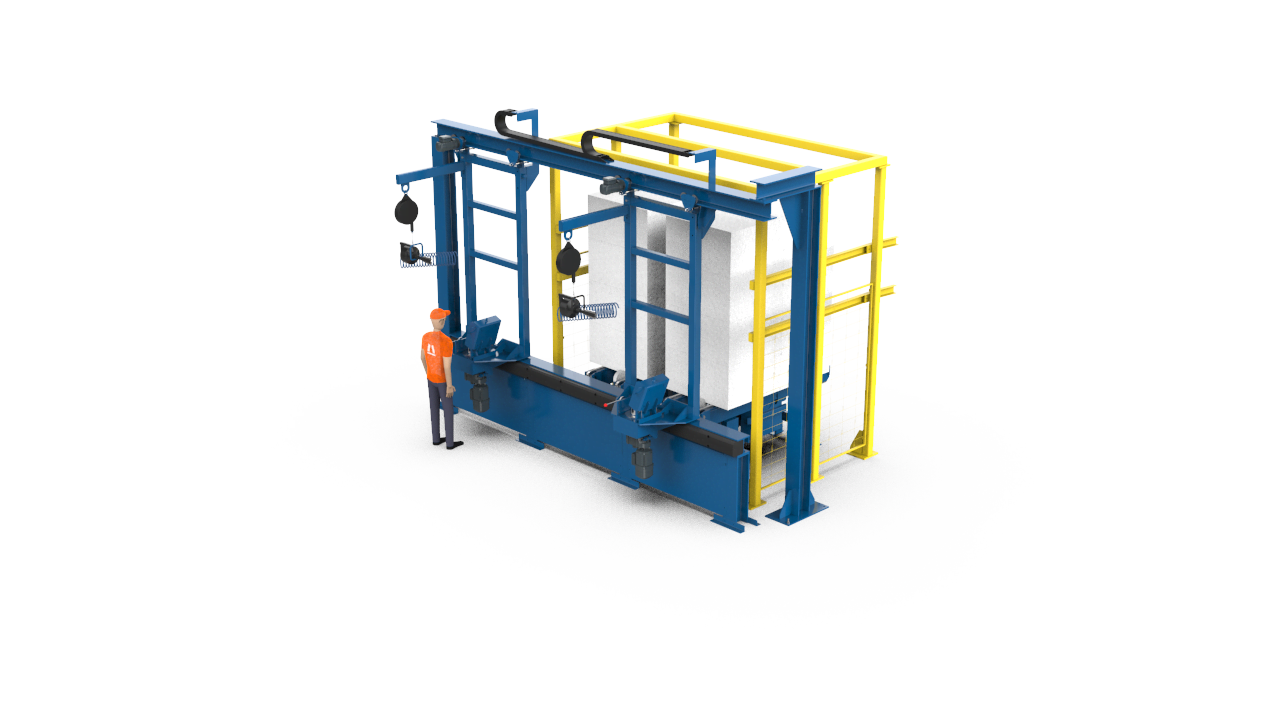

FMW Dewiring Solution – Semi Automatic Unit Dewiring (SA 8)

How can Semi Automatic Unit Dewiring (SA 8) Improve your Pulp & Paper Operations?

The pulp and paper industry is constantly evolving, with a supplementary growing focus on sustainability and eco-friendliness. This growth is driven by increasing demand for sustainable paper products and a shift towards environmentally responsible practices. One area where improvements can be made is in the dewiring process, which is often labor-intensive, time-consuming, and poses safety risks to workers. Introducing the Semi Automatic Unit Dewiring Solution (SA 8) – a solution designed to enhance efficiency, safety, and productivity in your pulp and paper operations.

FMW’s Semi Automatic Unit Dewiring Solution (SA 8) prioritizes operator safety while delivering a cost-effective solution for efficient pulp bale handling.

Key features of the Semi Automatic Unit Dewiring

- Labor Efficiency: By reducing the need for manual labor, this system allows a single operator to handle the process, cutting labor costs and minimizing the risk of injuries associated with manual dewiring.

- Speed and Productivity: The semi-automatic system is faster than manual dewiring, capable of processing a higher volume of materials in less time, which leads to increased overall productivity.

- Consistency: Automated elements of the system ensure consistent and uniform results, reducing variability and ensuring a higher quality end product.

- Improved Safety: The system is designed with safety features to protect operators from potential hazards, such as sharp wires or heavy materials, reducing the risk of accidents and injuries.

How it works:

The Semi Automatic Unit Dewiring Solution (SA 8) is installed on the crash protection of the unit receiving conveyor. Operators manually cut the wires of the units with a pneumatic hand cutting tool and place them into the wire winder, which automatically coils the wires. The coiled wire bundle is then manually removed by the operator.

Why to choose a Semi Automatic Unit Dewiring (SA 8)?

The Semi Automatic Unit Dewiring Solution (SA 8) is an ideal choice for medium-scale facilities looking to improve their dewiring processes without investing in a fully automated solution. It offers a balance between automation and manual intervention, providing a versatile and cost-effective alternative to manual dewiring.

Conclusion

Investing in a Semi Automatic Unit Dewiring Solution (SA 8) can significantly improve your pulp and paper operations by reducing labor costs, increasing productivity, and enhancing worker safety. To learn more about the benefits of the Semi Automatic Unit Dewiring system and how it can be tailored to your specific needs, contact FMW today.

Discover more about FMWs Pulp Bale Handling Solutions.

Learn more about our comprehensive range of solutions, from fully automatic pulp bale dewiring to efficient pulp handling systems, all engineered with a focus on safety, efficiency, and customization. Our solutions are designed to seamlessly integrate with your existing operations, ensuring maximum productivity and minimum downtime.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.