FMW Waste Paper Processing – Equal Flow Technology EFT

Is Your Pulping Drum Operating at Its Full Potential? Unlock Higher Productivity with FMWs EFT

The global waste recycling services market is growing at an unprecedented rate. In an industry where efficiency and productivity are crucial, it’s essential to optimize your pulping drum operations. FMW’s Equal Flow Technology (EFT) system is designed to address this challenge, ensuring continuous material flow and maximizing processing capacity for pulping drums.

The EFT Solution: Optimizing Pulping Drum Operations

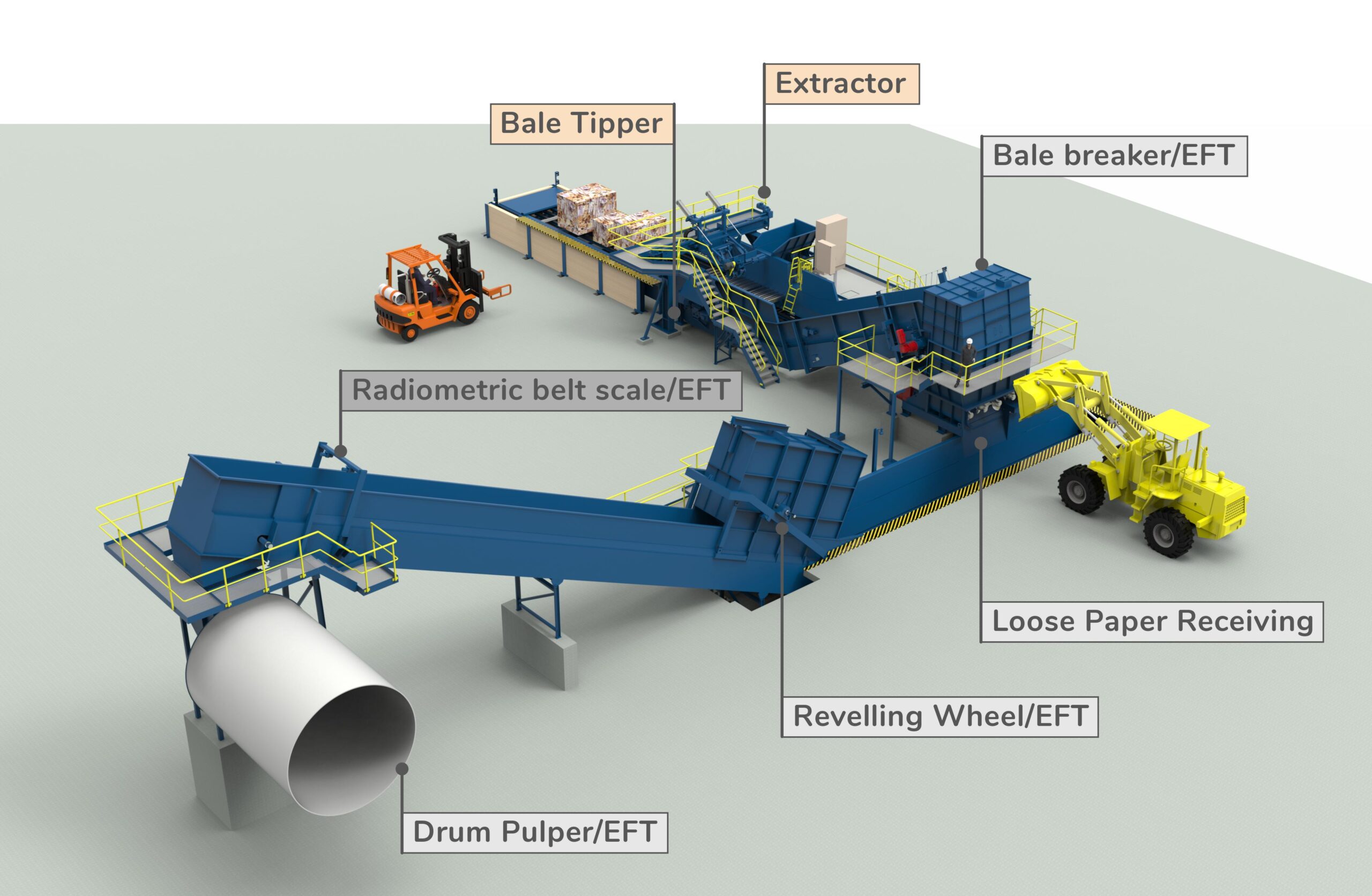

Traditional pulping drum feeding methods can lead to uneven material flow, inconsistent product quality, and reduced capacity. FMW’s EFT system provides a reliable and proven solution to these issues. By employing a two-step technique that includes a volumetric equalizer and a radiometric scale-controlled mass flow mechanism, the EFT system ensures a constant and uniform material flow into the pulping drum. This process not only maximizes the drum’s capacity but also maintains consistent product quality, meeting industry standards. The system usually consists of three components: a Bale Breaker, a Revelling Wheel and a Drum Pulper.

Efficiently regulate the combination of incoming materials to achieve a well-balanced blend, whether it’s ONP-OMG or loose materials.

Key Features of FMWs Equal Flow Technology

The EFT system offers several advantages that directly impact your bottom line:

- Higher Drum Capacity: By ensuring continuous material flow, the EFT system significantly enhances the drum’s processing capacity, allowing for higher throughput.

- Consistent Product Quality: The EFT system maintains a constant retention time, ensuring uniform product quality, and meeting industry standards.

- Cost-Effective Chemical Metering: Precise metering of chemicals is made possible with the EFT system, optimizing their usage and reducing operational costs.

- Reduced Downtime: With controlled material flow, the risk of jams and downtime is minimized, leading to more efficient operations.

- Controlled Feed Mixture: The EFT system offers the flexibility to control the mixture of incoming materials, ensuring a balanced blend, such as ONP-OMG or loose materials.

How it works:

The system employs a two-step technique, a volumetric equalizer and a radiometric scale controlled mass flow.

FMW’s EFT-System provides continuous material flow and ensures maximum processing capacity for the pulping drum.

Why Choose FMW EFT System?

When it comes to optimizing your pulping drum operations, the EFT System is the ideal solution. Its proven technology and reliable performance ensure that your pulping drum works at its full potential, delivering higher productivity, reduced costs, and increased operational efficiency.

Conclusion

In conclusion, the EFT system is a game-changer for pulping drum operations in the pulp, paper, energy, chipboard, and recycling industries. Discover how the EFT system can transform your pulping drum operations by contacting our experts for a personalized consultation.

Discover more about FMWs Wastepaper Handling Solutions.

The quality of the raw materials used directly impacts the final product quality. Wood chips, the primary raw material, need to be uniform in size and free from impurities to ensure a smooth and efficient production process. FMW Industries’ screening solutions provides a technology that effectively separates oversized chips and fines, leaving only high-quality material for further processing.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.