FMW Wood Chip Screening Solution – ReChipper

Optimize Your Chip Quality with FMWs ReChipper

The global pulp and paper machinery market is expected to grow. To keep pace with this growth and maintain a competitive edge, it’s crucial to invest in technology that optimizes production efficiency and reduces costs. One area that can significantly impact production efficiency is wood chip screening and processing. Inefficient chip handling can lead to lower yields, wasted resources, and increased energy consumption.

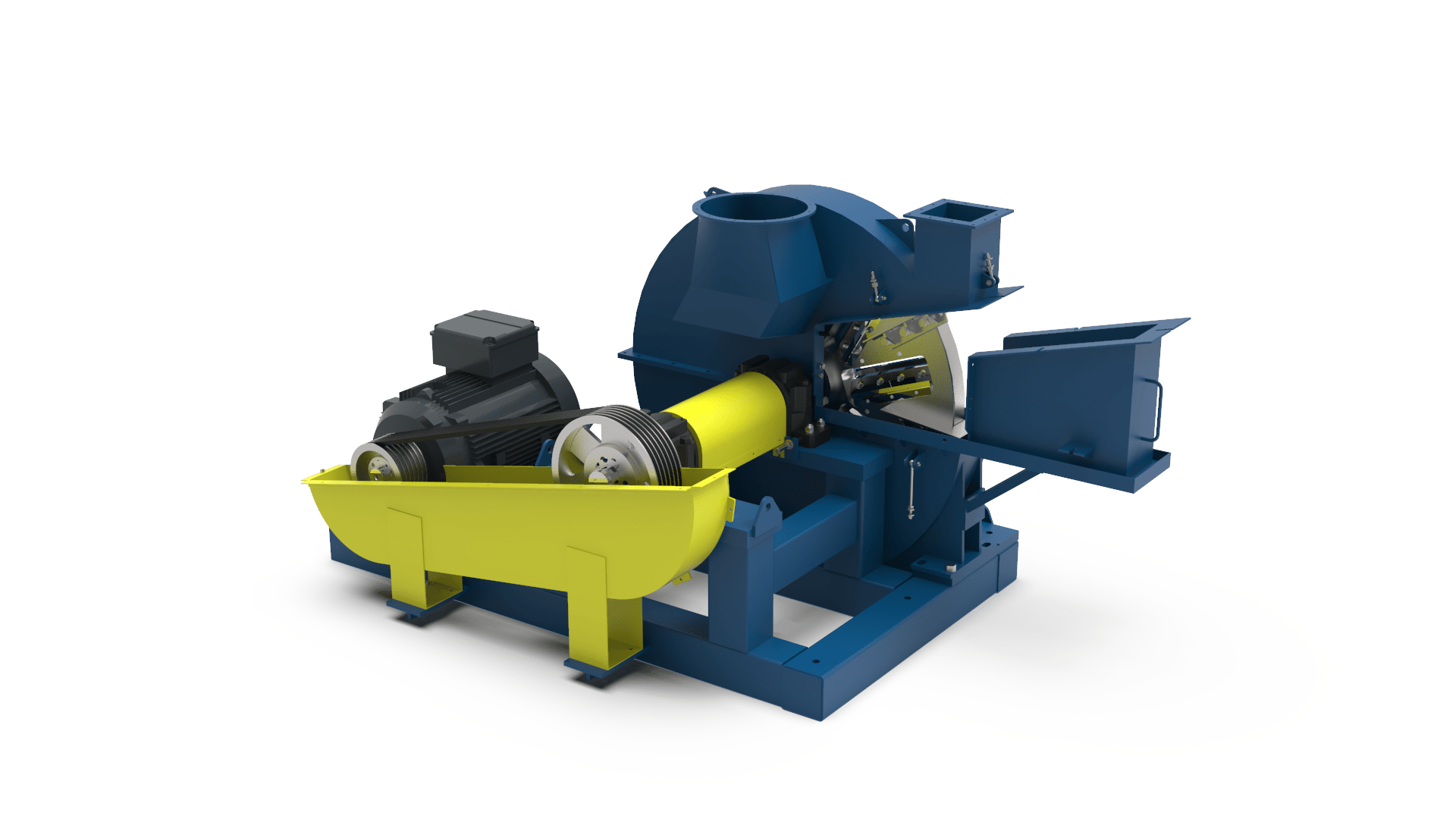

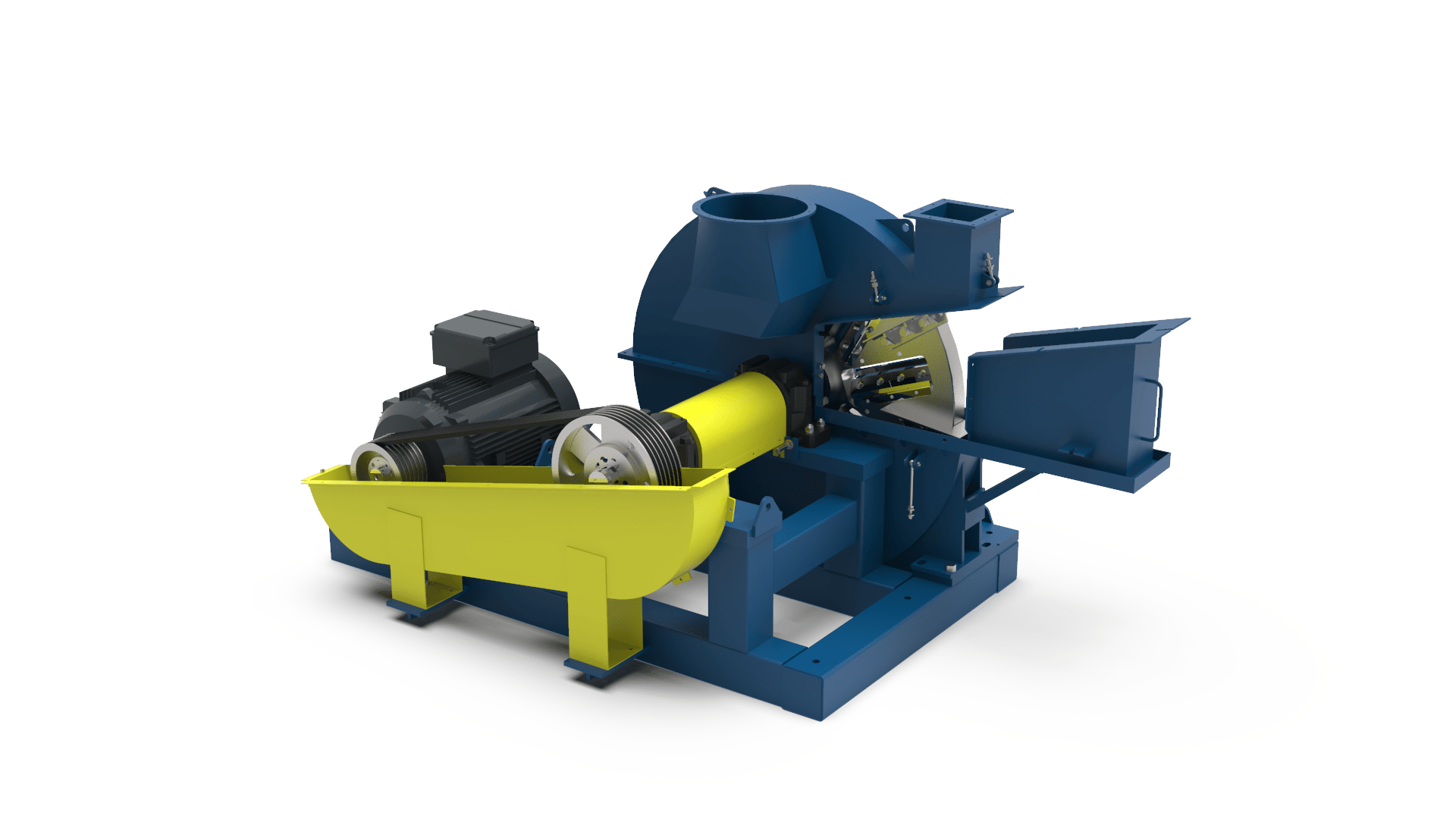

The FMW ReChipper addresses the challenges of oversized and over-thick chips in the material flow. By efficiently cutting these overzised chips into the perfect size, the Re-Chipper ensures optimal chip quality for downstream processes, ultimately improving your yield and reducing costs.

With easily replaceable and pre-set blades, the FMW ReChipper offers a convenient and low-maintenance solution for wood chip processing.

Keyfeatures:

- FMW Re-Chipper is designed with a multi V-spout for optimal gravity infeed

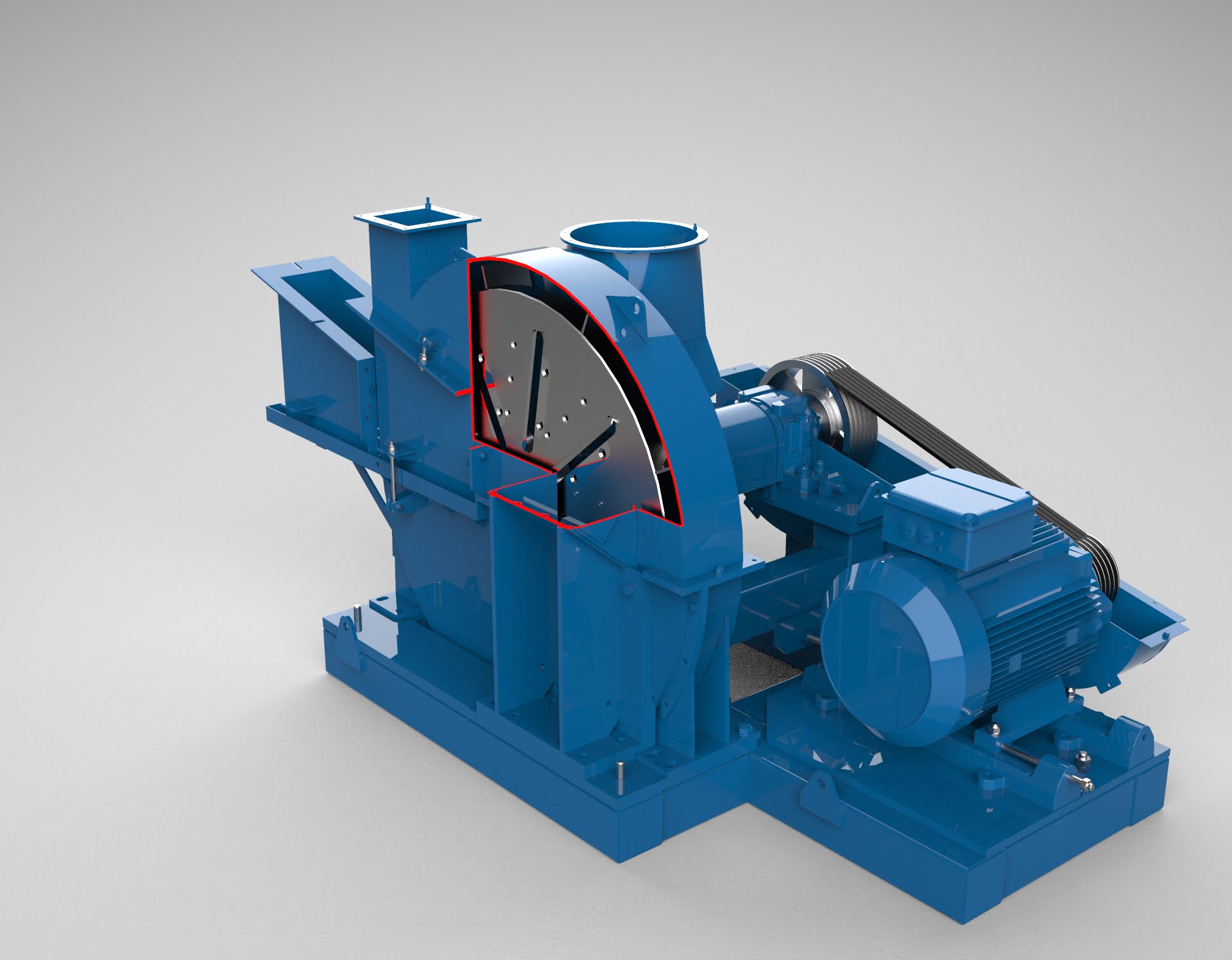

- High speed disc with max. numbers of knives to avoid fines production

- Rigid „knife-trough-disc“ design to process all hard & softwood species

- Easy access to knives and bed knife

- Prepared for air re-circulation

How it works

The FMW ReChipper is used to cut material such as pines, oversized and over-thick chips which are discharged within the Chip-Screening.

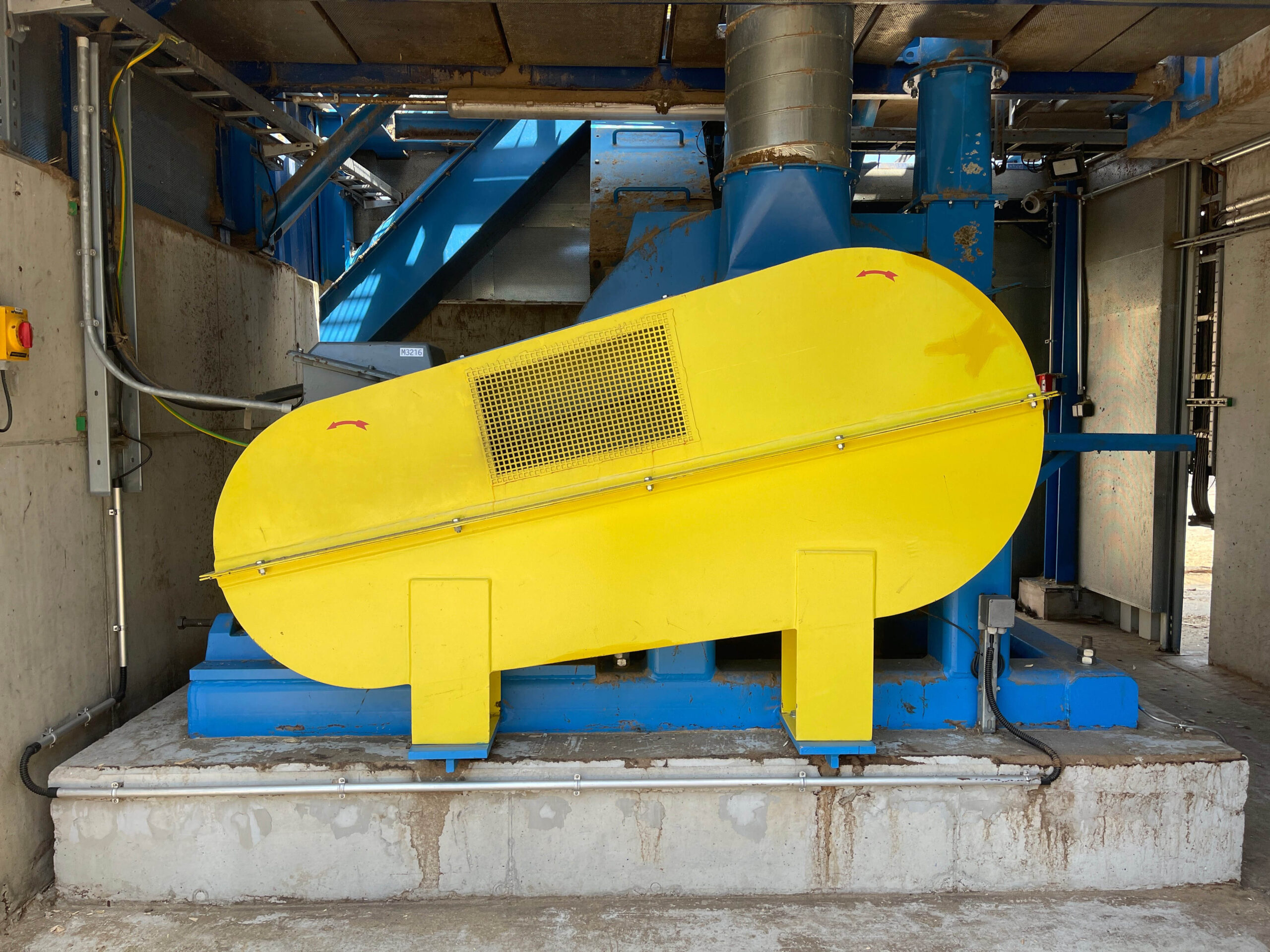

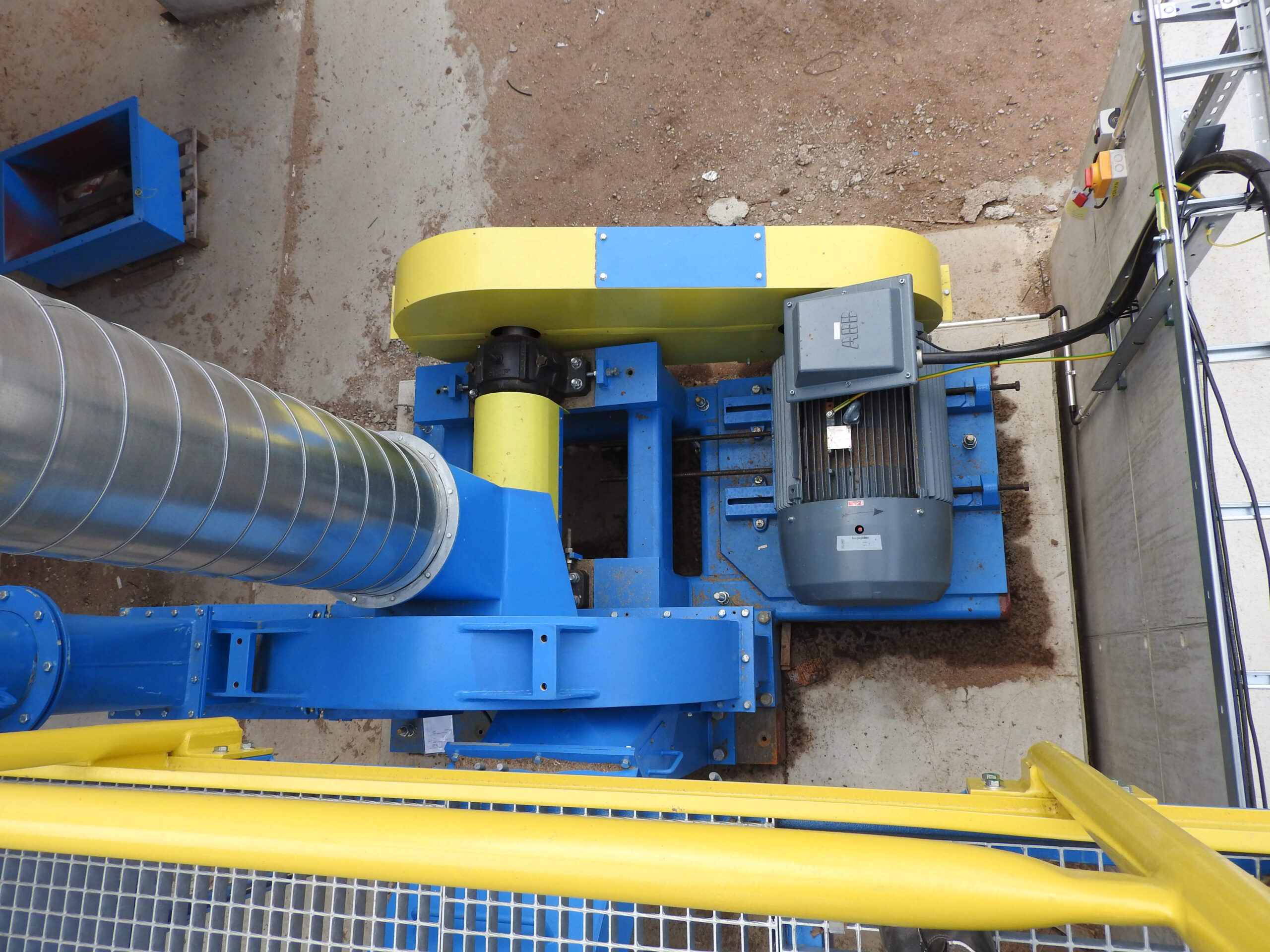

The material to be processed is fed into the chipping spout. Inside the ReChipper, a chipping disc rotates and cuts the material to the desired length. The chips are then blown back onto the Chip Screen for re-screening.

The chipping disc is easy to reach to facilitate regular maintenance.

This process improves production efficiency, quality, and productivity while reducing operating costs, raw material usage, and energy consumption.

Why Choose the FMW ReChipper

- One size machine up to 130 m³/h / 4600 ft³/h throughput capacity

- Standard knife and bed knife design, easy changeable and re-grindable

- Easy knife access for easy maintenance

- Comes along as one solution with the new FMW Chip Screen Type WCS or as a single machine

Conclusion

The FMW ReChipper is a cost-effective way for optimizing chip quality in the pulp and paper industry. With its unique features and backed by FMW’s decades of experience as a reliable and trustworthy partner, you can trust the Re-Chipper to deliver exceptional results. Don’t miss the opportunity to enhance your chip processing efficiency and stay competitive in the market. Contact FMW today for a consultation on how the ReChipper can improve your chip processing efficiency.

Discover more about the FMW Screening Solutions

The quality of the raw materials used directly impacts the final product quality. Wood chips, the primary raw material, need to be uniform in size and free from impurities to ensure a smooth and efficient production process. FMW Industries’ screening solutions provides a technology that effectively separates oversized chips and fines, leaving only high-quality material for further processing.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.