FMW Screening Solution – Chip Screen

Maximizing the Yield and Efficiency of Your Wood Chip Handling Process

The growth of the pulp and paper market is driven by the rising demand for sustainable paper products and advancements in paper manufacturing technology. With these trends, mill management professionals must optimize their processes to remain competitive.

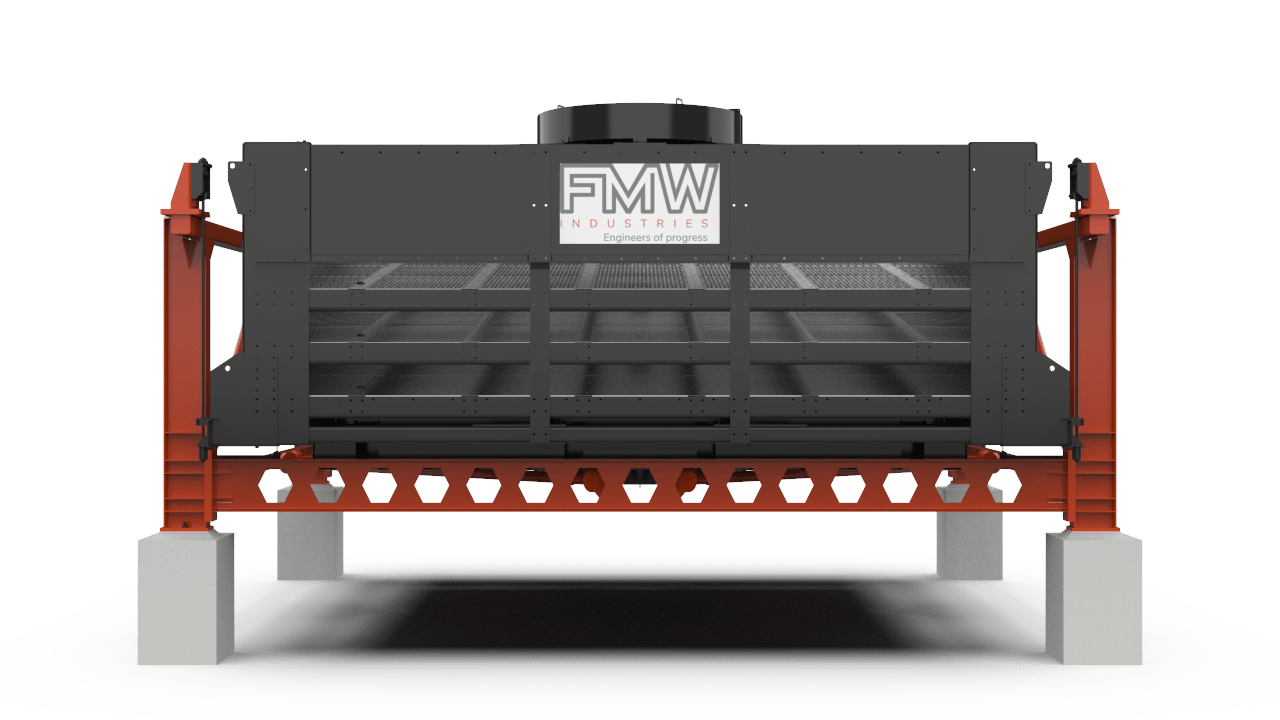

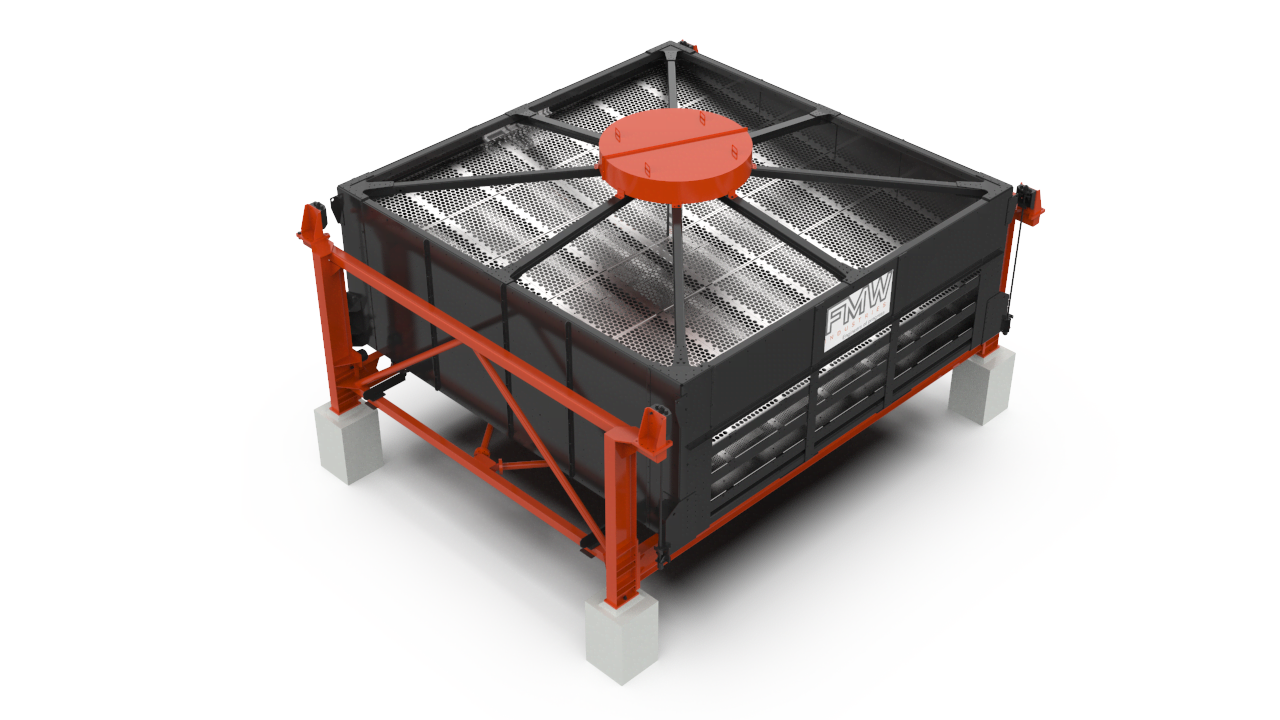

Introducing the FMW Chip Screen – an innovative solution designed to improve your wood chip handling process, boost your productivity, and increase your bottom line.

The FMW Chip Screen reduces wood chip blockage, needing only occassional cleaning.

Unique benefits of FMW Chip Screen:

- High-quality screening at maximum yield, ensuring only acceptable material is retained

- Space-saving design, easily fitting into various plant layouts

- Three inclined screening decks (optionally in stainless steel available) for optimal separation efficiency

- Bolted construction for enhanced structural integrity

How it works:

The Chip Screen efficiently removes impurities such as oversized chips and fines from the material flow. Its three screen decks, each with different perforations, separate the material into distinct fractions. The oversized material remains on the top screen deck and is transported to the Re-Chipper and cutted into the desired lenght and blowed back to the screen for re-screening. The remaining two screen decks separates the accept material. The bottom screen deck seperates the fines.

Why Choose the FMW Chip Screen

By opting for the FMW Chip Screen, you’ll benefit from a custom-made solution that delivers:

- Enhanced production efficiency and quality

- Reduction in operating costs, raw material usage, and energy consumption

- Increased yield and productivity

- Low maintance and cleaning

Conclusion

By incorporating the FMW Chip Screen into your operations, you can ensure that you remain competitive in the rapidly evolving pulp and paper industry. Learn more about this innovative solution and explore how it can transform your wood chip handling process.

Contact us today to discuss your requirements and learn more about how the chip screening system can improve your yield.

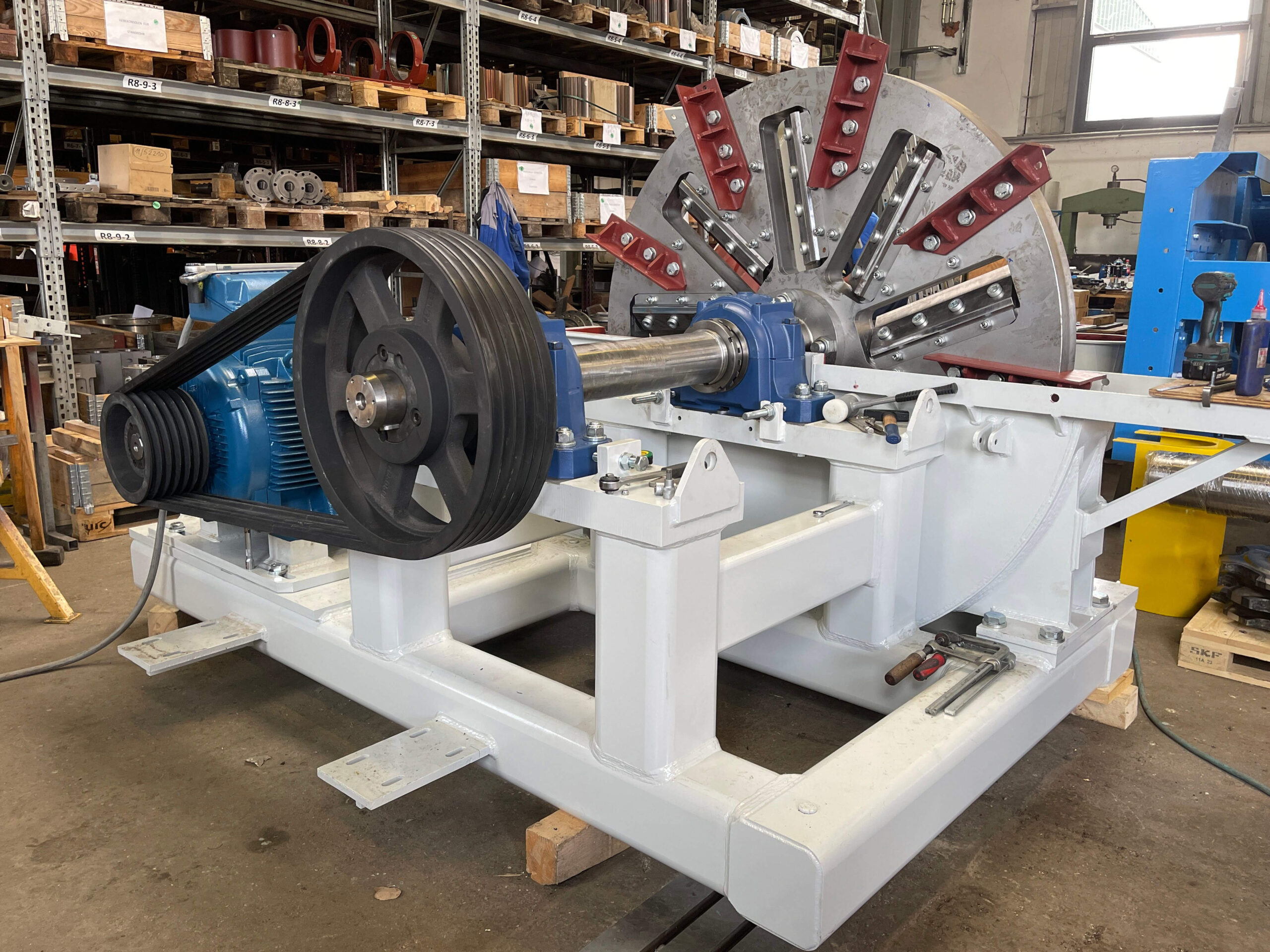

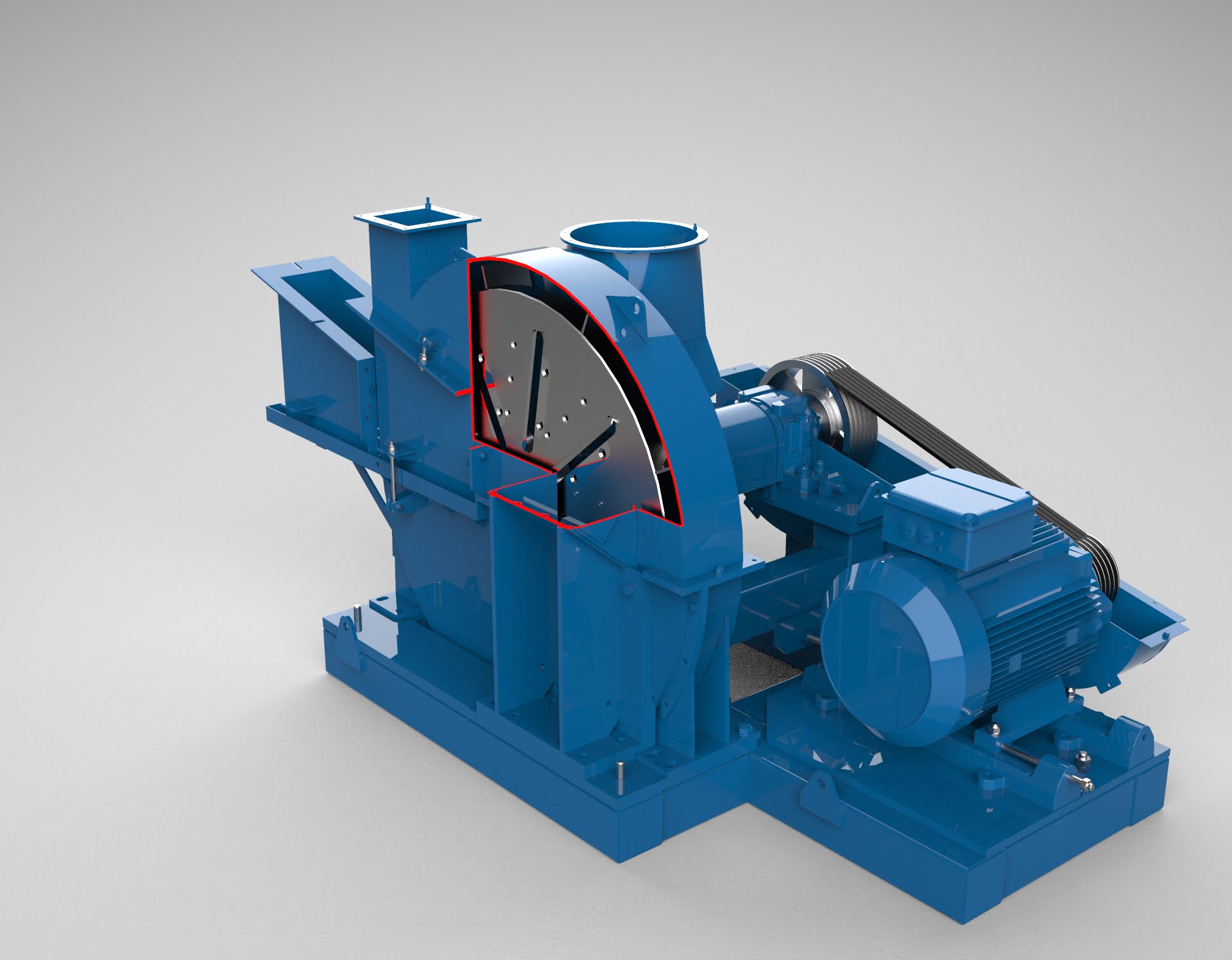

Discover more about the FMW Re-Chipper

The Re-Chipper plays a crucial role in eliminating oversized chips for re-screening, by cutting them to the desired length. This process not only enhances the quality of the final product but also contributes to the overall efficiency of the production process.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.